STOP VIBRATION,

REDUCE BREAKDOWNS, SAVE THOUSANDS IN DOWNTIME!

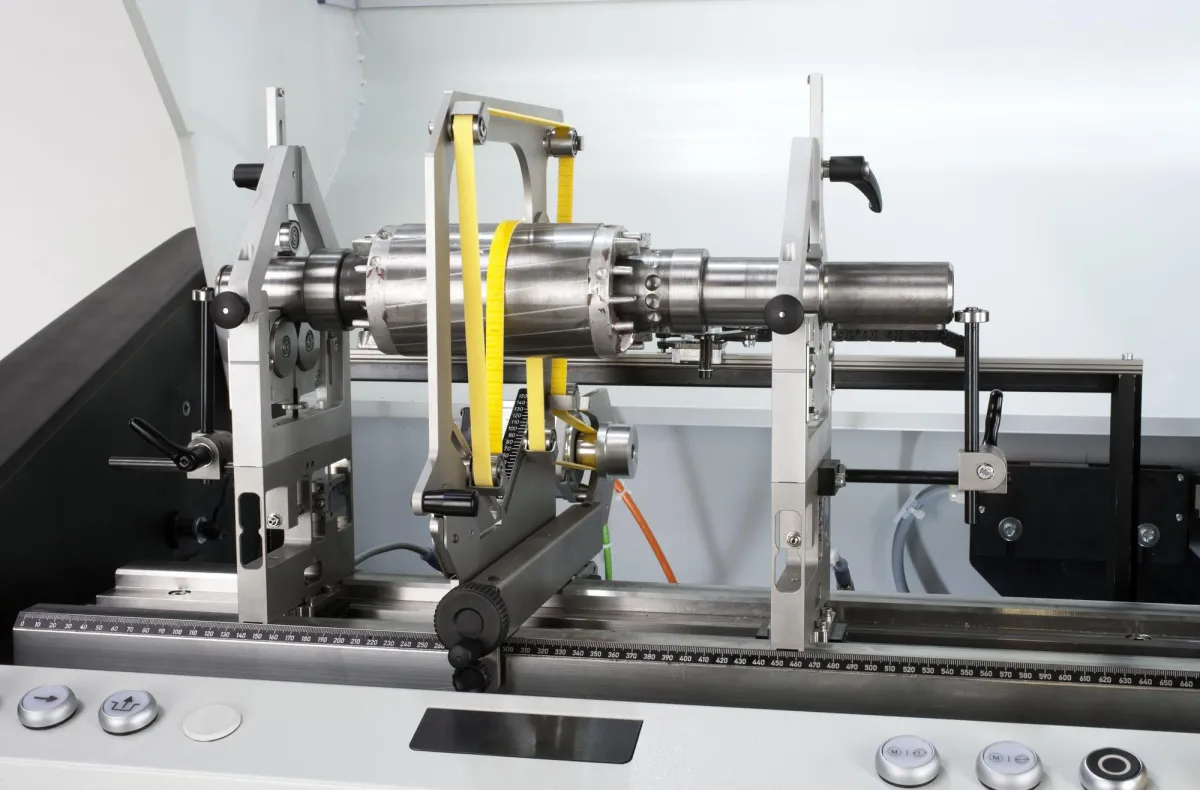

Precision dynamic balancing for Augers, fans, Impellers, Drums, industrial rotors, And more! If It Spins, We can Balance It. Serving Alberta operators with fast turnaround and certified results. We are Edmonton's Balancing Experts, Proudly Serving All Of Western Canada.

STOP VIBRATION,

REDUCE BREAKDOWNS, SAVE THOUSANDS IN DOWNTIME!

Precision dynamic balancing for Augers, fans, Impellers, Drums, industrial rotors, And more! If It Spins, We can Balance It. Serving Alberta operators with fast turnaround and certified results. We are Edmonton's Balancing Experts, Proudly Serving All of Western Canada.

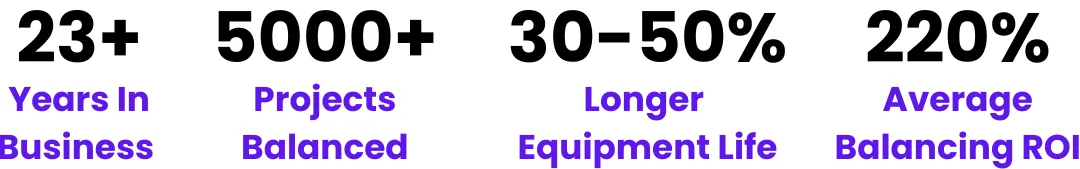

23+

Years In Business

5000+

Projects Balanced

30-50%

Longer Equipment Life

220%

Average Balancing ROI

TRUSTED BY

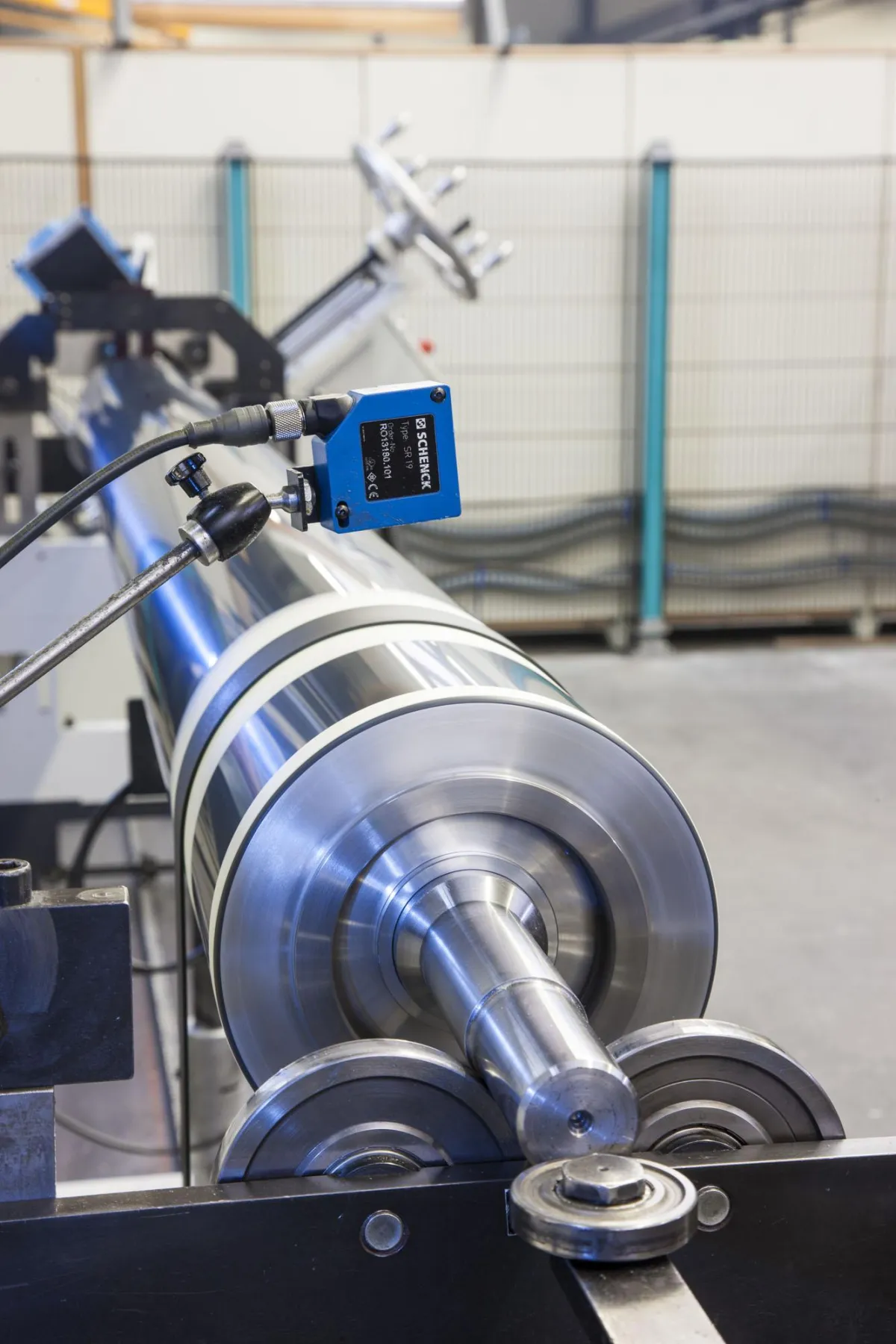

Struggling With Vibration? We Fix EXACTLY That!

Vibration is the leading cause of machinery failure, often damaging bearings and structure over time.

Balancing benefits include reduced noise, longer bearing life, less structural stress and improved safety.

Struggling With Vibration? We Fix EXACTLY That!

Vibration is the leading cause of machinery failure, often damaging bearings and structure over time.

Balancing benefits include reduced noise, longer bearing life, less structural stress and improved safety.

Super Simple 3 Step Process

Step 1) Request a quote

Fill out our short form with your equipment details, this takes less than a minute.

Step 2) We call you within 5 minutes

One of our professional balancing technicians will contact you within 5 minutes and confirm the best service options.

Step 3) Get back online fast!

Your balanced equipment will run smoother, last longer, and keep your operation producing!

Ready to save money?

Helping Businesses Save Thousands!

Service Rig Drums

Lost Rig Time (Downtime)

Avg service rig daily cost (crew, equipment, trucking, etc.): $12,000–$18,000/day (depending on location in Alberta).

If vibration takes the rig offline for repairs → you’re burning thousands per day with no revenue.

Accelerated Equipment Wear

Bearings, u-joints, seals, gearboxes wear out much faster.

Typical premature component failure costs:

Driveshaft or U-joint replacement: $3,000–$8,000

Bearing/seal repairs: $2,000–$5,000

A day of running unbalanced = taking months off component lifespan.

Safety & Risk Costs

Vibration can lead to catastrophic shaft failure → high risk of injury and unplanned rig shutdown.

Insurance claims, lost contracts, and liability can add tens of thousands.

Don't worry, we can help!

Frequently Asked Question

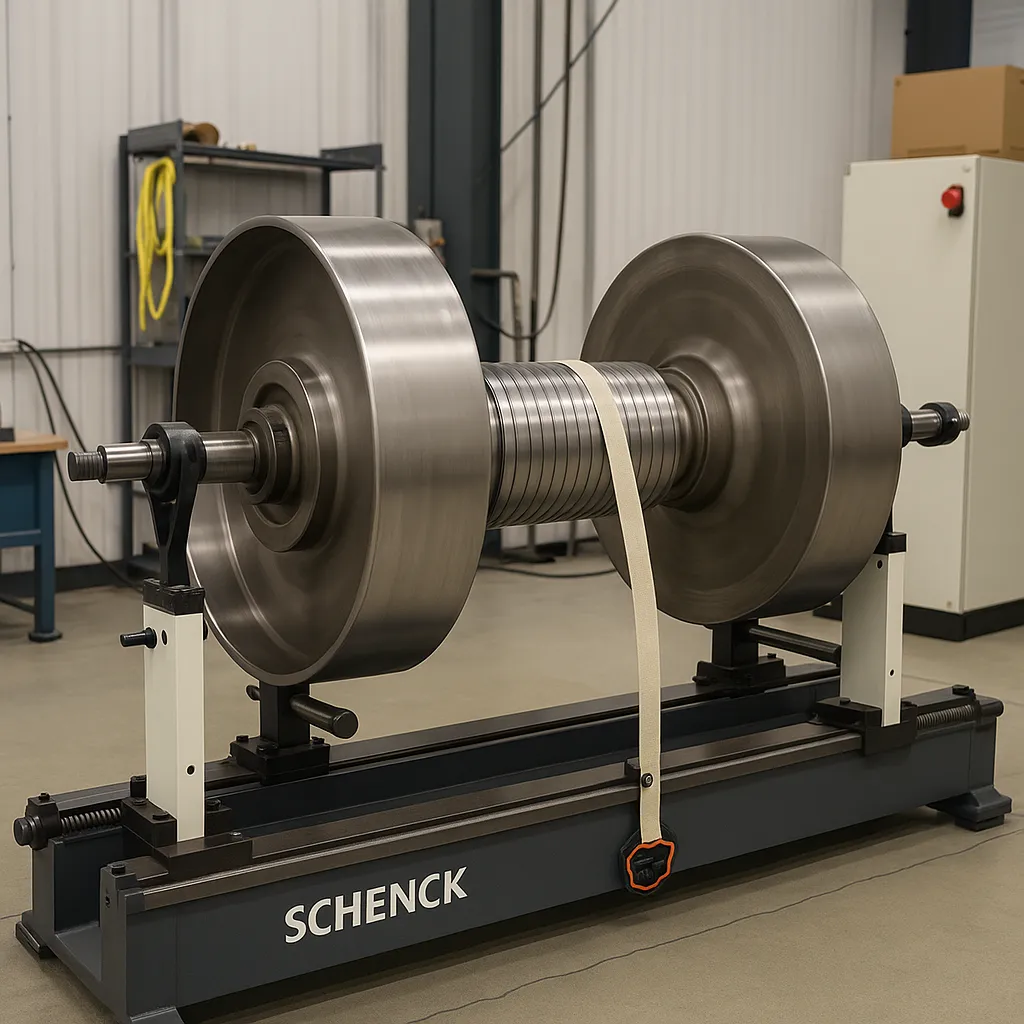

What type of equipment can you balance?

We can balance anything from a 10 pound rotary fan, to a 6000 pound drum, if it spins, we can likely balance it!

What spec can you balance to?

We can balance to a G1.0 spec.

Can you do both static and dynamic balancing?

Yes, absolutely!

How fast can you complete a job?

Most jobs are completed within 2-4 Days depending on it's complexity, however we also offer same day emergency services for balancing.

Can you handle bulk balance jobs?

Yes, Absolutely! We have a large shop with plenty of floor space to handle bulk balance jobs.